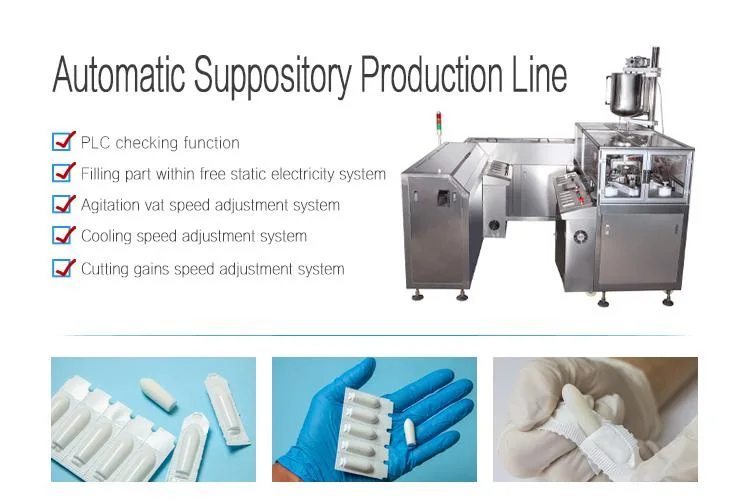

Pharmaceutical Suppository Production Line Suppository Machine Suppository Filling System

Products Description Automatic suppository filling production line has a stable and efficient manufacturing process, fil

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | SupLab-Series |

| Customized | Non-Customized |

| Condition | New |

| Warranty | 5 Year |

| Air Pressure | 0.6MPa |

| Volume of Storing Vessel | 50L |

| Water Consumption | 50kg Per Circle |

| Contour Dimension | 3200mm*3000mm*2300mm |

| Air Consumption | 1.5m3 |

| Deviation | <±;2% |

| Adapting Base Material | EMI-Synthesis Fatty Acid Lipo-Glycerol, Glycerol G |

| Suppository Shape | Bullet, Torpedo, Duck-Mouth Ect,. |

| Dose Per Unit | 0.5-5ml |

| Capacity | 8000-12000 Pieces/Hour |

| Transport Package | It Wrapped by Packed Into Export Standard |

| Specification | 2750*1250*1380mm |

| Trademark | LTMP CHINA |

| Origin | China Zhejiang |

| HS Code | 3315961642 |

| Production Capacity | 25 Sets/Mouth |

Product Description

Products Description

Automatic suppository filling production line has a stable and efficient manufacturing process, filling, freezing, sealing andother production processes to complete the whole process, and the production capacity is 8000-12000grain/hour.

Production process:

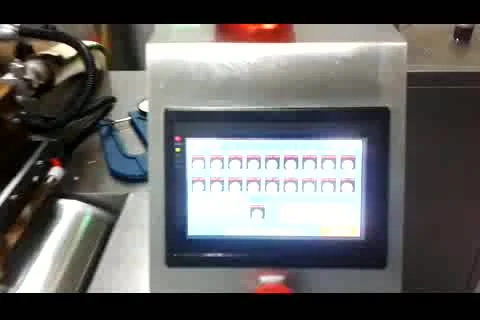

From automatic suppository shell forming, to the filling station of liquid medicine, Recirculating cooling set (liquid to solid),Continuous sealing with batch number, Transfer finished cutting (the number of cutting grains can be set arbitrarily on the touch screen, 1-10 grains can be cut at will)

-- Suitable for the production of special shape such as bullet head, torpedo shape and duck bill. -- Adapt material: synthetic fatty acid glycerol, glycerin gelatin, polyethylene glycol etc.

Product Paramenters

|

Filling part within free static electricity system.

Agitation vat speed adjustment system

Cooling speed adjustment system

Cutting gains speed adjustment system

Notice: end product grains can be set 4/5/6/7gains. The machine can product PVC/PE

Product Highlights

-- The insertion type linear perfusion mechanism can be used to locate accurate, not dropping, and not hanging wall; Thesingle-grain measurement is 0.5-5g and the filling error is plus or minus 2%.

02. Production capacity

-- The production capacity is 4500-5000 grain/hour.

-- The temperature sensor and microcomputer control system are used to realize high precision thermostatic control.

03. Siemens PLC control system

-- The equipment adopts PLC programmable control and man-machine interface operation, easy operation, convenient adjustment,accurate temperature control and smooth operation.

04. Servo high precision filling system

-- Filling, freezing, sealing and other

production processes are fully automatic.

-- Filling piston by servo motor with stroke

rule, easy to observe, stable action, no jitter and splash phenomenon, load online adjustable, high precision and easy to adjust!

05. exclusive circulation of water cooling system

-- latest circulating water cooling technology, which can solve the phenomenon of slag falling off and easy fracture when themedicine is torn apart.-- exclusive circulation of water cooling system advantages of thick tail edge, tear off residue.-- The temperature is adjustable.

06. Finished product

The sealing seal should be well sealed, with neat appearance and good value of not less than 99.%.If you want to know more, please send us an inquiryProduct Details

Company ProfileOur CompanyZhejiang LeadTop Pharmaceutical Machinery Co.,ltd well known as LTPM China. Since year 1996, we are start manufacturing Oral Solid Dosage Pharmaceutical Machinery includes Mixing Machine, Drying Equipment, granulation line, IBC Bin and Bin Washing Machine. As year passed, LTPM China absorb advanced domestic and abroad technology, we export machinery to more than 30 countries all over the world. LTPM China is considered one of the major Pharmaceutical Machinery Supplier and exporter in China mainland. Professional, Enthusiasm, Service and Team Work has been always our value to create for our Staff and customers. As year 2012 we position our value as "A Pharma Machinery Division, For A Better Life", creating a Win-Win Platform for our clients and staff for a better life is our vision.Our Machinery Manufacturing WorkshopImported CNC Machining Centre makes all parts process accurate. Own R&D team with more than 20 years engineering expereince, can customize the equipment and packaging line to your satisfaction.Professional Business TeamWarm, professional business team, careful response to your inquiry, timely response rate of more than 93%, higher than the average level of the industry.Our CertificatesISO, CE, SGS, BV Certified Company.Packing & Shipping

All machine delivery with anti rust spray, film wrapping and Sea shipping affordable wooden box.

FAQQ: How many different types of suppository machine you have? We are the starter for this product, what is your suggestion?

A: We have Four different type machine according to different production capacity requirement, They are SupLab-1, SupLab-2, SupLab-7 and SupLab-15. For the freshman in suppository field, we will suggest client to use our smallest model first, it is for both R&D and Production purpose. It comes with Forming, Filling, Colling, Sealing and Cutting. It is an Ideal starter machine

Q: We have limit length in our workshop, but we need biggest production capacity machine, what is your suggestion?

A: We can make the machine as U shape which will save many space on length

Q: Compare to the other manufacturer, what is your product advantage?

A: We manufacture the main parts like filling pump, filling cylinder and piston cylinder all by ourselves that we can achieve the best accuracy on the machine. We are the first manufacturer who does servo transaction on suppository machine, so we get matured technology in this field

Q: Does you machine comes with Heating hopper and Stir Function? A: Yes, this is our standard structure for the machine.

Related Products

-

![Metal Powder Coating Machine System Package with Electrostatic Powder Coat Gun + Spray Booth + Curing Drying Oven]()

Metal Powder Coating Machine System Package with Electrostatic Powder Coat Gun + Spray Booth + Curing Drying Oven

-

![High Effective Portable Old Aging Transformer Oil Purification Series Ty]()

High Effective Portable Old Aging Transformer Oil Purification Series Ty

-

![Small Lab Softgel Encapsulation Machine/Soft Capsules Vitamin E/Fish Oil/Paintball Making and Filling Equipment]()

Small Lab Softgel Encapsulation Machine/Soft Capsules Vitamin E/Fish Oil/Paintball Making and Filling Equipment

-

![CE Approval Mobile Mineral Turbine Oil Purification System (TY]()

CE Approval Mobile Mineral Turbine Oil Purification System (TY