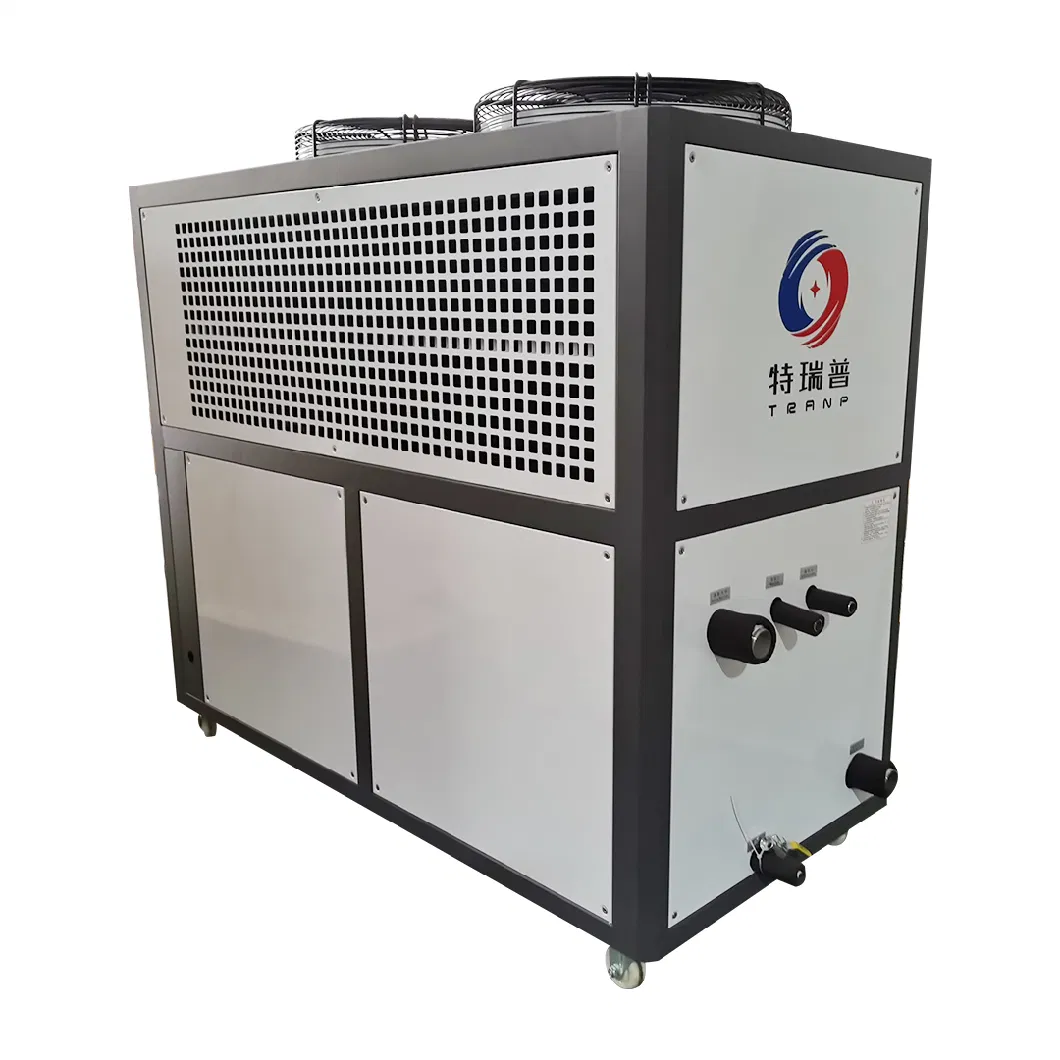

Air Cooled Chiller Unit for Milk Cooling

Package Size 200.00cm * 180.00cm * 170.00cm Package Gross Weight 200.000kg Industrial Air Cooled Water Chiller Unit for

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | SGS-200 |

| Cooling Method | Air-cooled |

| Unit Structure | Integral |

| Selected Voltage | 220V/50HZ |

| Compressor Number | 1 |

| Noise Level | Low |

| Application Fields | Food Processing |

| Application Machine | Machining Center |

| Certification | ISO, CE |

| Condition | New |

| Usage | Chilled Water, Milk Cooling, Chemical Industry etc |

| Component | Compressor, Evaporator, Expansion Valve, Condenser |

| Transport Package | Plywood Box |

| Specification | ISO9001: 2008, SGS |

| Trademark | Tranp |

| Origin | Guangzhou, China |

| HS Code | 8418692090 |

| Production Capacity | 200 Sets/Per Month |

Packaging & Delivery

Package Size 200.00cm * 180.00cm * 170.00cm Package Gross Weight 200.000kgProduct Description

Industrial Air Cooled Water Chiller Unit for Milk Cooling

The air-cooled screw flooded unit uses an advanced 5:6 high-performance screw compressor as the refrigeration "heart" to match high-quality condensers and evaporators, and is equipped with brand-name electrical control components. Suitable for all kinds of cooling and heating places.

Characteristics of the industrial water chiller

1. Energy-efficient compressor

The unit adopts scroll reciprocating compressors with high customer satisfaction, wide coverage, and excellent energy efficiency ratio. The compressor comes with a variety of protection functions, which greatly extends the service life. It meets production needs to the maximum and has significant energy saving effect.

2. High energy efficiency condenser

The industrial chiller condenser is made of imported copper pipes with high-precision processing equipment. The surface of the copper tube is processed into a trapezoidal rib tube, the heat transfer coefficient is greatly enhanced; the inner wall of the copper tube is smooth as a mirror, the water resistance is reduced, it is not easy to scale, and it is easy to clean and maintain.

3. High energy efficiency evaporator

The evaporator of the industrial chiller adopts imported copper pipes, which are processed into internal and external threads, which greatly increases the heat exchange effect and the energy efficiency ratio.

4. Mature and stable frozen components

The expansion valve adopts original products such as Emerson, Sporlan and other famous brand; the pressure controller is Japan Saginomiya; the filter is American Eco; the pressure gauge is Shanghai Fengshen and other well-known brands. It can effectively ensure the stable operation of the refrigeration system.

5. Stable and accurate control system

Intelligent control system, remote control and monitoring, simple operation, convenient installation, low failure rate and high safety factor.

6. Safety protection device

The safety devices installed in industrial chillers include: compressor overload and overheat protection, high and low pressure protection, fusible bolts, reverse and phase loss protection, insufficient water flow protection, frequent compressor startup protection, etc. It can effectively ensure the normal operation of the unit and prolong its service life.

Part 2.

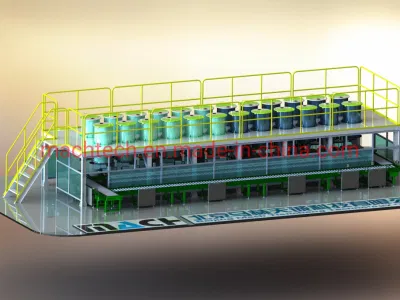

The scope of application of industrial chillers

Scope of application: food and beverage, chemical industry, papermaking, medicine, electroplating, injection blow molding, cleaning, ultrasonic and other industries.

Part 3.

Equipment picture of industrial water chiller